-

Small Cookie/Candy Jar

Regular price €37,00 EURRegular priceUnit price per -

Medium Cookie/Candy Jar - Red-Pink Drip Glaze

Regular price €44,00 EURRegular priceUnit price per -

Medium Cookie/Candy Jar - Green-Lilac Drip Glaze

Regular price €44,00 EURRegular priceUnit price per -

Medium Cookie/Candy Jar - Cherry

Regular price €44,00 EURRegular priceUnit price per -

Large Ashtray

Regular price €42,00 EURRegular priceUnit price per -

Wisteria Petal Vase

Regular price €120,00 EURRegular priceUnit price per -

Medium Vase

Regular price €38,00 EURRegular priceUnit price per -

Lilac Hearts Baking Dish

Regular price €89,00 EURRegular priceUnit price per -

Hearts Baking Dish Green

Regular price €89,00 EURRegular priceUnit price per -

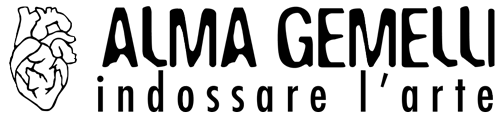

Lilac Strawberries Bread Cloche

Regular price €54,00 EURRegular priceUnit price per -

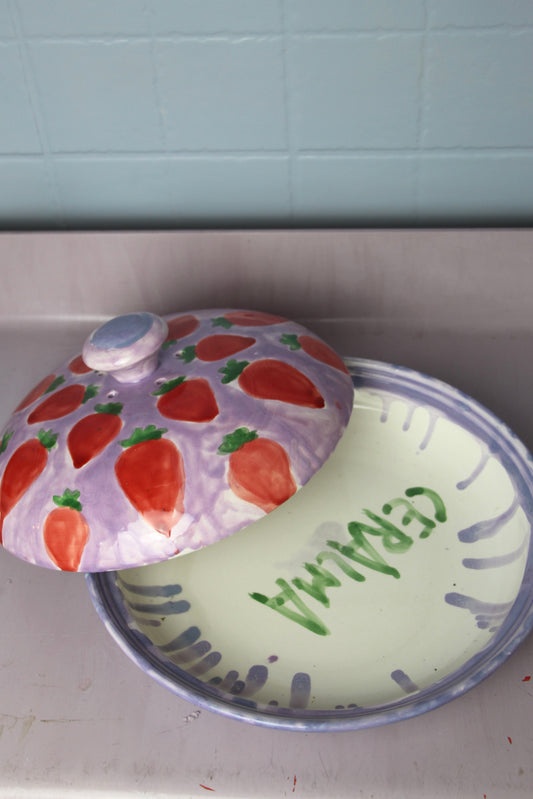

Small Heart Vase

Regular price €54,00 EURRegular priceUnit price per -

Large Round Strawberries Vase

Regular price €64,00 EURRegular priceUnit price per -

Ceralma Pink & Azure Drip Vase

Regular price €120,00 EURRegular priceUnit price per -

Large Flower-Shaped Trinket Dish

Regular price €79,00 EURRegular priceUnit price per -

Small Squadratino Red Drip Vase

Regular price €19,00 EURRegular priceUnit price per -

Tondino Ceralma Small Heart Vase

Regular price €19,00 EURRegular priceUnit price per -

Strawberry Pitcher

Regular price €79,00 EURRegular priceUnit price per -

Cherry Pitcher

Regular price €79,00 EURRegular priceUnit price per -

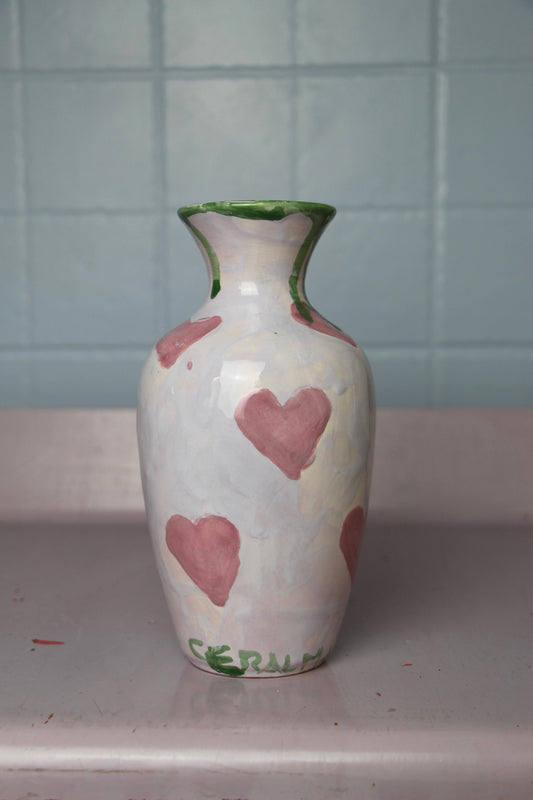

Large "Mi Amo" Vase

Regular price €77,00 EURRegular priceUnit price per -

Large Flower Vase

Regular price €77,00 EURRegular priceUnit price per -

Large Strawberry Vase

Regular price €77,00 EURRegular priceUnit price per -

Medium "Cordone Ombelicale" Vase

Regular price €120,00 EURRegular priceUnit price per -

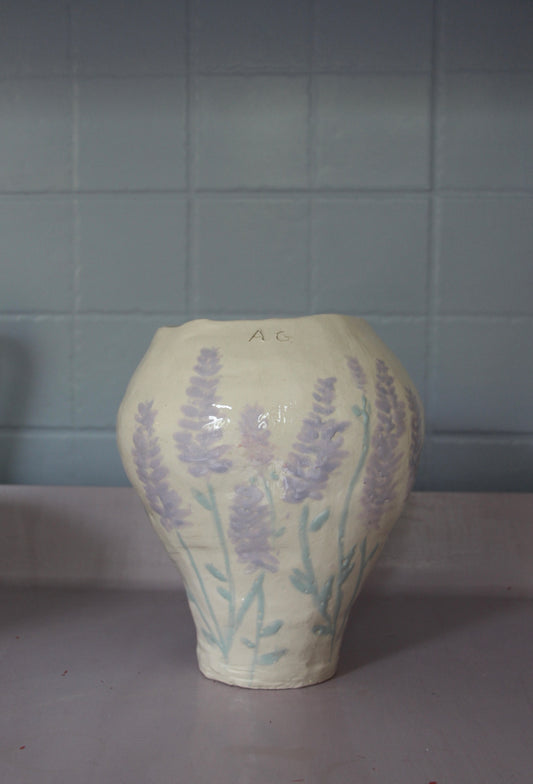

Lavender Vase

Regular price €120,00 EURRegular priceUnit price per

The soul of the collection

Creating Ceralma is a technique that requires a great deal of time, effort, and patience. There are two methods used: the Plus and the Basic. Both techniques share the same raw material for the initial crafting phase of the piece: white bisque.

The Plus Technique: The white bisque is worked by hand, intentionally leaving it with a freeform shape, complete with fingerprints and imperfections. Each piece is thus created one at a time in a very time-consuming process.

The Basic Technique: For pieces made on the potter's wheel, molds are created for series production, allowing for a faster process.

Once the piece is formed, it is left to dry in a dry place for about 20 days. It is then placed in a kiln to bake at 950 degrees Celsius for 12 hours for its first firing. After cooling, the coloring process begins for each individual piece. Alma Gemelli uses only natural materials, in this case, a lead-free powder glaze. The decoration is done freehand, piece by piece.

The final step is the coating, which involves dipping the object into a clear glaze. This is a vitreous, glass-like coating that starts as a powder and is processed into a liquid for application. This process makes the product durable and suitable for everyday use. The piece is then fired for a second time, again at 950 degrees Celsius. Once the kiln has cooled (which takes about 24 hours), the finished CerAlma pieces can be removed, ready to be used.